14-Layer High Density Interconnect (HDI) PCB Built on FR-4 Tg170℃ with Immersion Gold

(Custom PCBs are tailored products; the images and specifications provided are for reference only.)

General Description

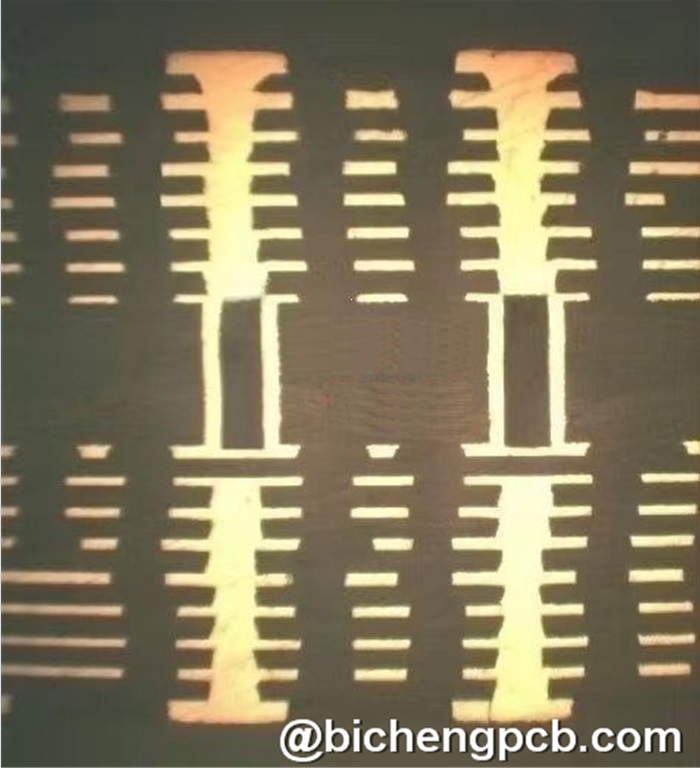

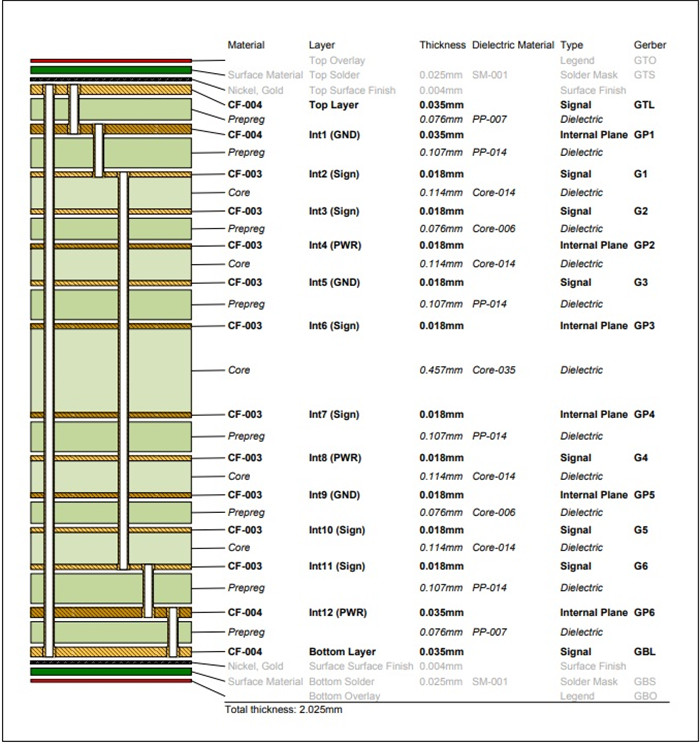

This 14-layer HDI printed circuit board is constructed on an FR-4 Tg170 substrate, designed for codec equipment applications. It has a thickness of 2.0 mm, features a white silkscreen on a green solder mask, and utilizes immersion gold on the pads. The PCB includes high-density interconnection layers with blind vias connecting L1-L2, L13-L14, and buried vias connecting L3-L4, L4-L12, and L12-L13. Microvias are stacked across different layers. The base material is sourced from ITEQ, with one board per panel. The PCBs are manufactured according to IPC 6012 Class 2 standards using the provided Gerber data, with each shipment containing 20 panels.

Our Advantages

1.ISO9001, ISO14001, IATF16949, UL Certified

2.Prototype to volume production capabilityB

3.16,000㎡ workshop

4.30,000㎡ output capacity per month

5.8,000 types of PCBs produced monthly

6.IPC Class 2 / IPC Class 3 compliance

7.First production eligible products rate: >95%

Applications of HDI PCBs

Automotive

GPS Trackers

5G WiFi

Embedded Systems

Smartphones and Tablets

Wearable Technology and Healthcare

Access Control Solutions

Aerospace

.jpg)

Parameter and Data Sheet

| Number of Layers | 14-Layer |

| Board Type | Multilayer PCB |

| Board size | 220mm x 170mm=4PCS |

| Board Thickness | 2.0 mm +/-0.16 |

| Board Material | FR-4 |

| Board Material Supplier | ITEQ |

| Tg Value of Board Material | 170℃ |

| PTH Cu thickness | ≥20 um |

| Inner Iayer Cu thicknes | 18 um (0.5oz) |

| Surface Cu thickness | 35 um (1oz) |

| Solder Mask Type and Model No. | LPSM, PSR-2000GT600D |

| Solder Mask Supplier | TAIYO |

| Solder Mask Colour | Green |

| Number of Solder Masks | 2 |

| Thickness of Solder Mask | 14 um |

| Type of Silkscreen Ink | IJR-4000 MW300 |

| Supplier of Silkscreen | TAIYO |

| Color of Silkscreen | White |

| Number of Silkscreen | 1 |

| Mininum Trace (mil) | 5.8 mil |

| Minimum Gap(mil) | 6.2 mil |

| Surface Finish | Immersion Gold |

| RoHS Required | Yes |

| Warpage | 0.25% |

| Vias | Blind vias L1-L2, L13-L14, buried vias L3-L4, L4-L12, and L12-L13, Through holes. |

| Thermal Shock Test | Pass, 288±5℃,10 seconds, 3 cycles. No delamination, no blistering. |

| Solderablity Test | Pass, 255±5℃,5 seconds Wetting Area Least 95% |

| Function | 100% Pass electrical test |

| Workmanship | Compliance with IPC-A-600H & IPC-6012C Class 2 |

Different Types of HDI PCBs

To simplify the classification of high-density interconnect PCBs, we define three types of HDI PCBs as follows:

1+N+1: PCBs that contain one-time laser drilling and pressing.

I+N+I (I≥2): PCBs that include two or more laser drilling and pressing steps, featuring staggered or stacked microvias across different layers.

Any Layer HDI: Blind and buried vias can be placed freely on various layers as per the designer's requirements.